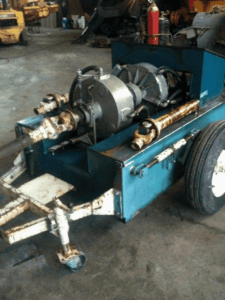

Despite its 56-gallon hydraulic oil reservoir and twin oil coolers, the M&W P2000 offered only limited test durations.

Although it was rated at 460 PTO horsepower @ 1159 RPM—twice the capacity of the earlier P400—this figure was misleading. The hydraulic pump manufacturer rated each pump at only 90 HP @ 1800 RPM, yielding a true combined capacity of just 180 horsepower.

The root design flaw lay in mismatched operating speeds. Many tractors of the era still operated at 540 RPM, far below the pumps’ rated speed. To compensate, M&W incorporated a 3:1 speed-increasing gearbox to elevate pump speed closer to 1800 RPM. But this workaround introduced cascading problems. As newer tractors moved to 1000–1300 RPM PTO speeds, the resulting gear and pump noise revealed an even more serious issue: cavitation. Starved of oil, pumps overheated internally. Even worse, cavitation induced sublimation—a damaging vacuum effect that stripped metal from gear teeth without melting—ultimately causing catastrophic pump failure, even on low-HP tractors or during cold starts.

Compounding the issue was the absence of a torque arm. The P2000 couldn’t measure torque, and M&W recommended waiting until hydraulic oil reached 140°F before reading power values. As temperatures rose, so did hydraulic pressure—and with it, wildly inflated gauge readings. Variance ranged from 10–15% or more. As the University of Nebraska succinctly put it, “We use [our M&W Hydro-gauge dynamometer] to warm tractors up before beginning our official test on a real dynamometer.”

By the early 1970s, AW Dynamometer began gaining traction in the ag market with its Prony brake designs, which could accurately measure torque. Meanwhile, tractors were getting larger and stronger—John Deere’s 8630 model, for example, produced 225 PTO horsepower and a 25% torque rise. Although the P2000 was “rated” to 460 horsepower, it failed rapidly in the field. Readings exceeding 285–295 HP were frequent; during torque rise, gauge spikes reached 320–330 HP. These inflated numbers sparked distrust—John Deere, relying on the Nebraska Tractor Test Lab for their ratings, knew their machines weren’t leaving the factory 25–30% over spec.

To resolve the discrepancy, John Deere held a comparative test in Waterloo, Iowa. They tested their in-house quality audit dynamometer, an AW Neb400, and M&W’s best P2000 against a John Deere 4840 tractor:

- A — Nebraska Tractor Lab: 180–181 HP

- B — John Deere Quality Audit: 177–178 HP

- C — AW Model Neb400: 180–181 HP

- D — M&W P2000: 196–198 HP

Note: Fuel was added before the AW test, explaining the slight increase.

The P2000 overstated power by 11%, affirming what field techs had long suspected. John Deere officially discontinued the use of M&W units for field diagnostics due to their unreliability.

Production issues further compounded M&W’s decline. With rising demand in the late ’70s and limited pump availability from Hydreco—alongside increasing warranty claims for failed pumps—M&W transitioned to Tyrone-brand pumps. Unfortunately, these lacked pressure-compensating wear rings and consistently failed under high load within hours.

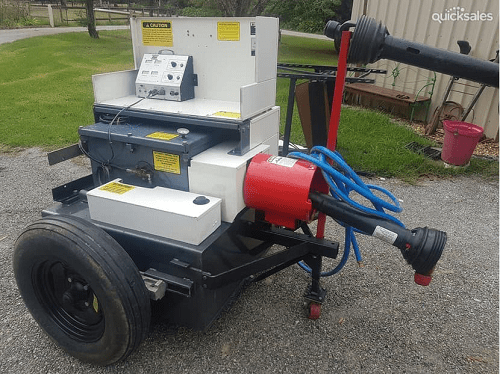

As a last effort to slow AW’s market ascendancy, M&W introduced the P4450—a water-brake design that finally measured torque. While it technically qualified as a true dynamometer, it still struggled during high torque, low RPM, and torque rise testing. Ultimately, it couldn’t rival the performance or reliability of AW’s Prony brake models.